Have you ever wondered how you can improve the performance of your hydraulic system while reducing noise and extending its life? The answer lies in using hydraulic lifter additive! They can make a significant difference in the efficiency and longevity of your machinery. In this blog post, we will explore the world of hydraulic lifter additives, discuss the benefits of using them, and provide tips for choosing the right hydraulic lifter additive and maintaining your hydraulic system properly. Let’s dive in!

Key Takeaways

Hydraulic lifter additives improve engine performance, reduce noise and extend the lifespan of hydraulic systems.

Choosing the right additive requires research into compatible brands, oil types and viscosity to ensure adherence to manufacturer specifications.

Adopting responsible practices for storage, handling & disposal of fluids/additives can help prevent environmental damage.

Understanding Hydraulic Lifter Additives

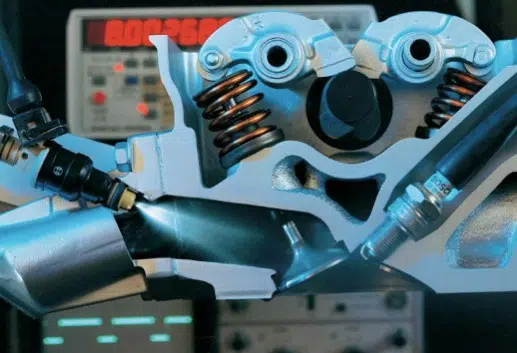

Hydraulic lifter additives are designed to enhance engine performance, reduce operational noise, and prolong the life of hydraulic systems. They come in various types, such as the Wynn’s Hydraulic Valve Lifter, which is an oil-soluble supplement that eliminates deposits inside the engine, thus reducing noise and improving efficiency. Another example is the LIQUI MOLY hydraulic lifter additive, suitable for all commercial motor oils in gasoline and diesel engines, both with and without diesel particulate filters. These additives play a crucial role in maintaining the performance of hydraulic systems and preventing hydraulic fluid leaks.

Understanding how hydraulic lifter additives work is the first step to appreciating their benefits. One significant aspect of their functionality lies in addressing internal hydraulic fluid leaks by improving the lubrication and sealing properties of the oil. By understanding the various hydraulic lifter additives available and their functions, you can make an informed decision on which additive is suitable for your system.

Benefits of Using Hydraulic Lifter Additives

Utilizing hydraulic lifter additives offers numerous advantages, such as preventing and diminishing hydraulic lifter noise, cleaning oil passages to eliminate oil flow restrictions, and restoring appropriate hydraulic lifter function.

Beyond noise reduction and wear prevention, hydraulic lifter additives also enhance hydraulic cylinder performance. They assist in cleaning oil passages and breaking down sludge and other deposits that could impede oil flow. This, in turn, helps maintain the performance of hydraulic cylinders by ensuring proper lubrication and reducing wear. The benefits of using hydraulic lifter additives extend not only to the individual components of the system, but also to the overall performance and longevity of the hydraulic equipment.

How Hydraulic Lifter Additives Work

Hydraulic lifter additives function by removing deposits, improving lubrication, and sustaining ideal viscosity. Viscosity is a measure of a hydraulic oil’s resistance to flow, and as temperature increases, the viscosity of engine oil will decrease. As temperatures drop, engine oil thickens and becomes increasingly viscous. This is opposite from when temperatures rise as the oil thins out. Monitoring for external leak issues is also an important aspect of maintaining a well functioning engine with the correct engine compression.

LIQUI MOLY hydraulic lifter additive enhances performance by cleaning oil holes and ducts in the oil circuit, which in turn boosts the functioning of oil pressure-filled timing chain tensioners, potentially reducing timing chain noise. Wynn’s Hydraulic Valve Lifter cleans away deposits inside the engine, further contributing to the overall effectiveness of the additive.

A grasp on how hydraulic lifter additives function facilitates a deeper understanding of their role in hydraulic fluids and their influence on your system’s performance.

Choosing the Right Hydraulic Lifter Additive

Considerations such as brand, oil type, and viscosity are key when choosing the right hydraulic lifter additive. Popular additives from LIQUI MOLY and other brands such as Castrol, Valvoline, and Mobil offer various benefits for different applications. It’s important to choose an additive that is compatible with your engine and adheres to the manufacturer’s specifications.

Beyond brand and compatibility, the type of oil is also a significant factor in the selection process. There are two main types of oils: mineral oils and synthetic oils. Mineral oils are derived from petroleum and are typically more economical than synthetic oils, while synthetic oils are manufactured and engineered to provide superior performance and protection. Understanding the differences between mineral and synthetic oils can help you make an informed decision when maintaining a well functioning hydraulic lifter system.

Most popular Hydraulic Lifter Additives from LIQUI MOLY and other brands

The most popular hydraulic lifter additive from LIQUI MOLY is their Hydraulic Lifter Additive, designed to reduce hydraulic tappet noise and compatible with all commercial motor oils for both gasoline and diesel engines. This additive can help reduce engine wear and tear, optimize performance, and minimize noise, making it a popular choice for many users.

Other brands of hydraulic lifter additives available on the market include Castrol, Valvoline, and Mobil. Each brand offers its unique formulation and benefits, catering to different applications and requirements. Comparing the benefits and differences of popular additives will help you discern the most suitable product for your engine oil and hydraulic lifter system, ensuring optimal performance and durability.

Mineral Oils vs. Synthetic Oils

Mineral oils are obtained from crude oil and contain contaminants. They are more cost-effective than synthetic oils, making them a popular choice for budget-conscious consumers.

However, when it comes to performance and longevity, synthetic oils have the upper hand. Synthetic oils can be formulated to provide better physical properties when compared to mineral oils. They possess a higher viscosity index, improved resistance to oxidation, and thermal degradation, ultimately offering enhanced performance and longevity.

Understanding the distinctions between mineral and synthetic oils empowers you to make an informed choice regarding the ideal oil type for your hydraulic lifter system and corresponding hydraulic lifter additive.

Viscosity Considerations

Viscosity is a crucial factor in technical fluids, affecting the system’s performance and efficiency. The viscosity index (VI) is utilized to measure the alteration in viscosity of hydraulic oil when the temperature fluctuates. The viscosity of an engine oil changes drastically with shifts in temperature if it has a low viscosity index. On the other hand, a high viscosity index provides better resistance to such temperature shifts. Hydraulic oil with a high viscosity index (VI) is typically recommended for applications with a broad range of ambient and/or operating temperatures.

When selecting a hydraulic lifter additive, one should take into account the viscosity of the oil. This is because the viscosity of the oil affects the flow rate and pressure of the hydraulic system. Taking into account the oil’s viscosity and its effect on system performance allows you to make a well-informed decision about the best hydraulic lifter additive for your system.

Application and Maintenance Tips

Proper application and maintenance of hydraulic lifter additives ensure optimal performance and system longevity. Here are some steps to follow.

Regularly monitor fluid levels and look for any signs of leakage.

Follow the manufacturer’s instructions for adding hydraulic lifter additives to your engine oil system.

Use the recommended amount of additive for your system size.

Run the system for a few minutes to allow the additive to circulate.

Regularly check and replace the engine oil as needed. By following these steps and maintaining your hydraulic lifter system, you can extend the life of your equipment and enjoy the benefits of improved performance.

Ensuring the proper application and maintenance of your hydraulic lifter system not only contributes to its longevity, but also helps prevent potential environmental damage. Responsible use of hydraulic lifter additives and disposal of used fluids and additives in accordance with local regulations and guidelines is crucial. By adhering to these practices, you can minimize the environmental impact of your hydraulic system and promote responsible use of additives.

Properly Adding Hydraulic Lifter Additive

Adding hydraulic lifter additive correctly involves following the manufacturer’s guidelines and ensuring compatibility with the existing fluid. Here are the steps to follow.

Check the manufacturer guidelines for the correct amount of additive to use.

A 300 ml container is sufficient for treating up to 6 liters of motor oil.

Add the recommended amount of additive to the motor oil.

Run the engine until it is warm after adding the additive for optimal results.

To ensure a lasting effect, it is advised to utilize the additive after each oil change.

When introducing a hydraulic lifter additive, follow these steps to ensure proper integration into your oil system.

Consider compatibility with the existing fluid.

Add the specified amount of hydraulic lifter additive to the engine oil.

Make sure the engine is warm.

Run the engine for a few minutes.

Adhere to the manufacturer’s guidelines for frequency of use.

By following these steps, you can ensure the proper integration of the additive into your hydraulic system and enjoy its benefits.

Monitoring Fluid Levels and Leak Detection

Keeping a close eye on fluid levels is essential for the smooth operation of your hydraulic system. Regularly checking the fluid levels and looking for any signs of leakage can help maintain engine oil and hydraulic system performance and prevent damage. If a leak is detected, prompt action should be taken to avoid further damage to the system.

Not only should you monitor fluid levels, but it’s also important to check hoses, fittings, and other components for signs of wear or damage. If a potential leaking fluid is identified, it is recommended to take the vehicle to a certified mechanic for repair. The mechanic will be able to pinpoint the origin of the leak and carry out the necessary repairs, ensuring the continued performance and longevity of your hydraulic lifter system.

Common Hydraulic Lifter System Issues and Solutions

Hydraulic systems can encounter a range of problems, including leaks, performance decline due to oxidation, and insufficient lubrication. By identifying these common issues and implementing the right solutions, such as repairing or replacing leaking components, utilizing a suitable hydraulic lifter additive, and regularly inspecting and replenishing fluids and additives, you can address these problems and maintain the optimal performance of your hydraulic lifter system.

Being mindful of the potential environmental repercussions of hydraulic lifter systems and their additives is indispensable. By implementing responsible practices in the storage, handling, and disposal of engine oil, technical fluids and additives, you can minimize the environmental impact and ensure compliance with relevant regulations. This not only contributes to the longevity and performance of your hydraulic lifter system, but also helps protect the environment.

Dealing with Hydraulic Cylinder Leaks

Hydraulic cylinder leaks can be resolved by replacing seals, tightening connections, or using hydraulic leak sealant to seal small leaks. Worn or damaged seals, loose connections, or corrosion can potentially cause hydraulic cylinder leaks. By regularly inspecting your hydraulic cylinders and addressing any issues promptly, you can prevent leaks and maintain the performance of your hydraulic system.

Beyond repairing leaks, maintaining adequate lubrication and ensuring the optimal functionality of hydraulic cylinders is vital. Regular inspection of hydraulic cylinders and the use of suitable hydraulic additives can help address internal leakage and improve the sealing properties of the oil, contributing to the overall performance of the hydraulic system. Hydraulic lifter additives for engine oil do not solve Hydraulic Cylinder Leaks and are not hydraulic fluid additives. Other specialized additives for hydraulic fluid can prevent hydraulic cylinder leaks.

Overcoming Poor Performance Due to Oxidation

Oxidation is a chemical reaction in which oxygen molecules react with other molecules, such as those found in hydraulic fluids. This reaction can lead to a breakdown of the fluid, resulting in decreased performance and efficiency. By using high-quality hydraulic fluids and additives with oxidation inhibitors, you can mitigate oxidation and minimize the risk of suboptimal performance due to oxidation.

Choosing the right hydraulic fluid and additive is key to combating poor performance as a result of oxidation. By choosing a fluid and additive that is compatible with your system and adheres to the manufacturer’s specifications, you can effectively address oxidation-related issues and prolong the lifespan of your hydraulic system. Hydraulic lifter additives are not suitable to address this problem.

Environmental Considerations and Responsible Disposal

Mindful environmental considerations and responsible disposal of engine oils, hydraulic fluids and additives are necessary to prevent damage and comply with regulations. The potential environmental impact of hydraulic lifter additives should be taken into consideration, as some additives may contain chemicals that can negatively affect the environment. By choosing environmentally friendly additives and adhering to local regulations and guidelines for disposal, you can minimize the environmental impact of your hydraulic system and promote responsible use of additives.

Beyond considering the environmental impact of hydraulic lifter additives, implementing responsible practices in their storage, handling, and disposal is of utmost importance. Proper containment and disposal of used hydraulic fluids and additives can help prevent environmental damage and ensure compliance with relevant regulations. By following these practices, you can contribute to the sustainability of your hydraulic system and the environment.

Preventing Environmental Damage

Preventing environmental damage involves proper storage, handling, and containment of engine oils, hydraulic fluids and additives. Here are some steps you can take to prevent leaks and spills that may harm the environment.

Store engine oils, hydraulic fluids and additives in a cool, dry place away from direct sunlight and other sources of heat.

Use appropriate containers and ensure they are properly sealed to prevent leaks.

Handle engine oils, hydraulic fluids and additives with caution to avoid direct contact with the environment.

Clean up any spills immediately using absorbent materials and dispose of them properly.

By following these guidelines, you can help protect the environment from potential damage caused by engine oils, hydraulic lifter fluids and additives.

Responsible practices and adherence to local disposal regulations and guidelines are essential when using hydraulic lifter additives. This includes disposing of used fluids and additives in a leak-proof container and taking them to a designated hazardous waste disposal facility. By implementing these practices, you can minimize the environmental impact of your hydraulic lifter system and contribute to the preservation of the environment.

Proper Disposal of Used Hydraulic Fluids and Additives

To properly dispose of used hydraulic fluids and additives, you must adhere to local regulations and utilize approved waste disposal facilities. Disposing of used fluids and additives improperly can lead to environmental damage, including contamination of soil and water supplies, as well as potential negative impacts on wildlife and human health. It is crucial to adhere to proper disposal practices to minimize the environmental impact and ensure compliance with relevant regulations.

When disposing of used hydraulic fluids and additives, it is important to contain them in a leak-proof container and dispose of them in accordance with local regulations. This may involve recycling, landfill disposal, or re-refining through distillation or distillation/hydrotreating. By following these responsible practices and adhering to local guidelines, you can help protect the environment and ensure the sustainability of your hydraulic system.

Summary

In conclusion, hydraulic lifter additives play a vital role in enhancing the performance, reducing noise, and extending the life of hydraulic systems. By understanding the different types of additives, their benefits, and how they work, you can make an informed decision on which additive is best suited for your system. Proper application and maintenance, along with responsible disposal practices, are crucial for ensuring the longevity of your hydraulic system and minimizing its environmental impact. Invest in the right hydraulic lifter additive and implement responsible practices to enjoy the benefits of improved performance and a longer-lasting hydraulic system.

Frequently Asked Questions

What does hydraulic lifter additive do?

Hydraulic lifter additive cleans away deposits that create noise and reduce engine efficiency, lubricates and releases sticking valves, and restores proper hydraulic lifter function to reduce wear.

What can I use to quiet noisy lifters?

To quiet noisy lifters, use a high-quality product such as Liqui Moly Hydraulic Lifter Additive or Rislone Engine Treatment.

Additionally, engine flushing can be particularly effective to prevent gummed up tappets and reduce noise levels.

How do you use Liqui Moly hydraulic lifter additive?

Use Liqui Moly hydraulic lifter additive by adding the contents of the 300 ml bottle (sufficient to treat up to 6 liters of motor oil) at any time.

Run the engine until warm after adding the product and use it again after each oil change for lasting effect.

What are the main benefits of using hydraulic lifter additives?

Hydraulic lifter additives can reduce noise, improve engine performance and prolong the life of hydraulic systems while also addressing hydraulic leaks, providing many tangible benefits for your engine.

These benefits include improved engine performance, reduced noise, and extended hydraulic system life. Additionally, hydraulic lifter additives can help address hydraulic leaks, providing further value to your engine.