Fuel injection systems are the unsung heroes of our vehicles, impacting their performance, efficiency, and even emissions. As technology advances, it’s essential to stay informed about the latest developments and how they can benefit your ride. In this blog post, you’ll gain insights into various types of fuel injectors, their components, common issues, and recent advancements in fuel injection technology. Let’s dive in and uncover the mysteries of fuel injection systems!

Key Takeaways

Understand fuel injection systems to maximize engine performance and reduce emissions.

EFI systems offer numerous advantages over mechanical fuel injection while understanding the various types of injectors can inform decisions regarding vehicle maintenance.

Fuel injector cleaning methods such as LIQUI MOLY Jetclean help optimize engine performance and increase efficiency.

Understanding Fuel Injection Systems

Fuel injection systems are designed to regulate the air/fuel mixture in an engine, including diesel engines, impacting:

horsepower

fuel economy

emissions

heat

efficiency

These systems have a significant role in the overall performance of an internal combustion engine.

Exploring the different types, components, and functions of fuel injection systems is key to understanding their intricacies.

Electronic vs Mechanical Fuel Injection

In the past, mechanical fuel injection systems were the norm, but they were complex and slow to respond when reducing throttle. Electronic fuel injection (EFi) has since taken over, offering numerous benefits over its mechanical counterpart. Some advantages of electronic fuel injection systems include:

More efficient engines

More powerful engines

More economical engines

Lower toxic emissions

The main distinction between early mechanical injection systems and contemporary electronic systems is the incorporation of an electronic engine control unit (ECU). The ECU gathers data from various engine sensors and adjusts the fuel delivery to optimize engine performance.

Importance of Fuel Injection Systems

Emissions compliance and fuel economy are largely ensured by fuel injection systems. They offer advantages such as:

Improved fuel efficiency

Precise fuel delivery

Reduced or eliminated air pollution

Enhanced performance on steep grades

With the ever-increasing emphasis on environmental responsibility, fuel injection systems have become indispensable components in modern engines.

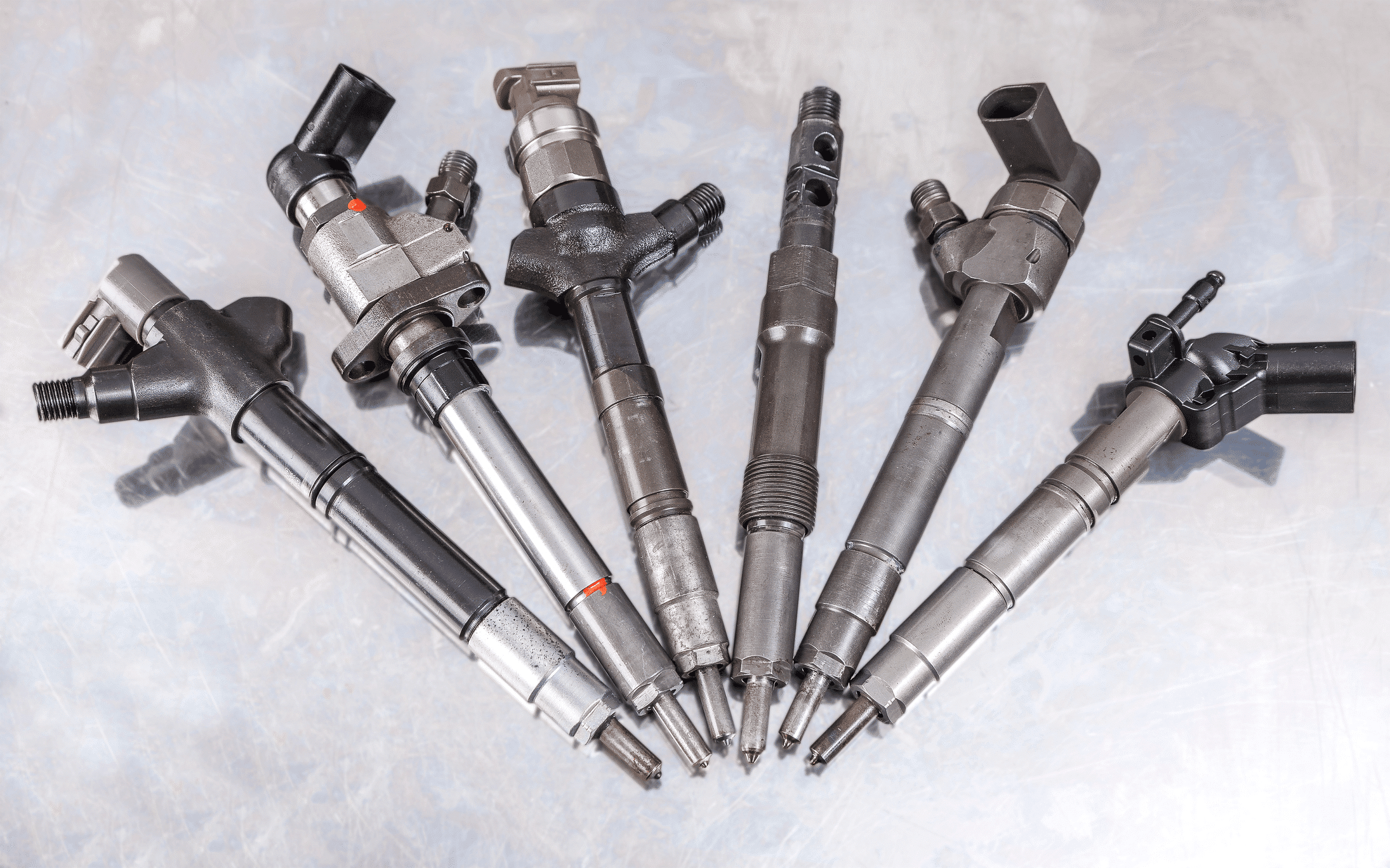

Types of Fuel Injectors

Fuel injectors come in various forms, with single-point, multi-point, and direct injection systems being the most common. Each type of fuel injector serves a specific purpose and has its advantages and disadvantages.

Being familiar with these different fuel injectors can guide your decisions regarding vehicle maintenance and performance.

Single-Point or Throttle-Body Injection

Single-point injection, also known as throttle-body injection, uses a single fuel injector for all cylinders in the combustion chamber. While this system was an economical solution for automakers to fulfill exhaust emission regulations and provide improved “driveability” compared to a carburetor, it had its drawbacks:

Limited control over fuel delivery to individual cylinders

Less precise fuel-air mixture

Reduced power and efficiency compared to multi-point injection systems

At high RPMs, single-point injection affected engine performance due to inadequate fuel supply, resulting in a rough ride quality. The fuel also condensed outside the intake manifold due to which a fraction of it was getting wasted. This consequently led to fuel wastage..

Single-point injection was prevalent in American cars and light trucks manufactured from 1980 to 1995. European cars had similar injection technology during the early/mid-1990s.

Multi-Point or Port Injection

Multi-point or port injection, on the other hand, injects fuel into the intake ports just upstream of each cylinder’s intake valve. This system provides improved fuel efficiency, enhanced engine performance, and reduced emissions.

However, synchronizing multi-point injection with piston rotation can be challenging, leading to uneven fuel distribution and decreased engine performance. Despite this drawback, multi-point injection remains popular in modern vehicles due to its overall advantages over single-point injection.

Direct Injection

Direct injection systems inject fuel directly into the cylinder, bypassing the intake valve or manifold. This method offers maximum fuel economy as its primary benefit. Direct injection has become increasingly popular in both gasoline and diesel engines due to its efficiency and precision in fuel delivery.

With the growing emphasis on fuel economy and emissions reduction, direct injection systems are becoming the standard in modern automotive engineering.

Components of a Fuel Injection System

Understanding the main components is vital to fully comprehend the workings of a fuel injection system. A fuel injection system consists of a fuel pump, fuel rail, and engine control unit (ECU). Each of these components plays a vital role in ensuring the efficient and precise delivery of fuel to the engine.

The fuel pump is responsible for delivering fuel from the fuel tank to the fuel rail. The

Fuel Pump

The fuel pump is responsible for pressurizing the fuel and supplying it to the injectors. It can be powered either electrically or mechanically by the engine. In a mechanical fuel injection system, the fuel pump pumps fuel at a pressure of 100 psi up to a fuel tank.

As a component that ensures the delivery of fuel at the correct pressure, the fuel pump is essential for optimal engine performance within a fuel injection system.

Fuel Rail

The fuel rail, another critical component of a fuel injection system, is a high-pressure tubing system that facilitates the delivery of fuel to the fuel injectors in an internal combustion engine. The fuel rail ensures even and regulated distribution of fuel to the injectors, preventing uneven fuel delivery and subsequently optimizing engine performance.

The fuel rail, which ensures consistent fuel flow and delivery, contributes to maintaining optimal engine performance and efficiency.

Engine Control Unit (ECU)

Lastly, the engine control unit (ECU) is responsible for monitoring and controlling the fuel injection process. The ECU performs the following functions:

Gathers data from various engine sensors

Adjusts the fuel delivery

Controls the idle speed

Optimizes ignition timing to optimize engine performance.

In some applications, the ECU also manages valve timing. The ECU plays a vital role in ensuring that the fuel injection system operates efficiently and effectively.

Common Fuel Injection Issues and Solutions

Like any complex system, fuel injection systems can encounter various issues that may impact their performance. Some common fuel injection problems include clogged injectors, leaking injectors, and faulty sensors.

Maintaining optimal engine performance and efficiency hinges on identifying and addressing these issues.

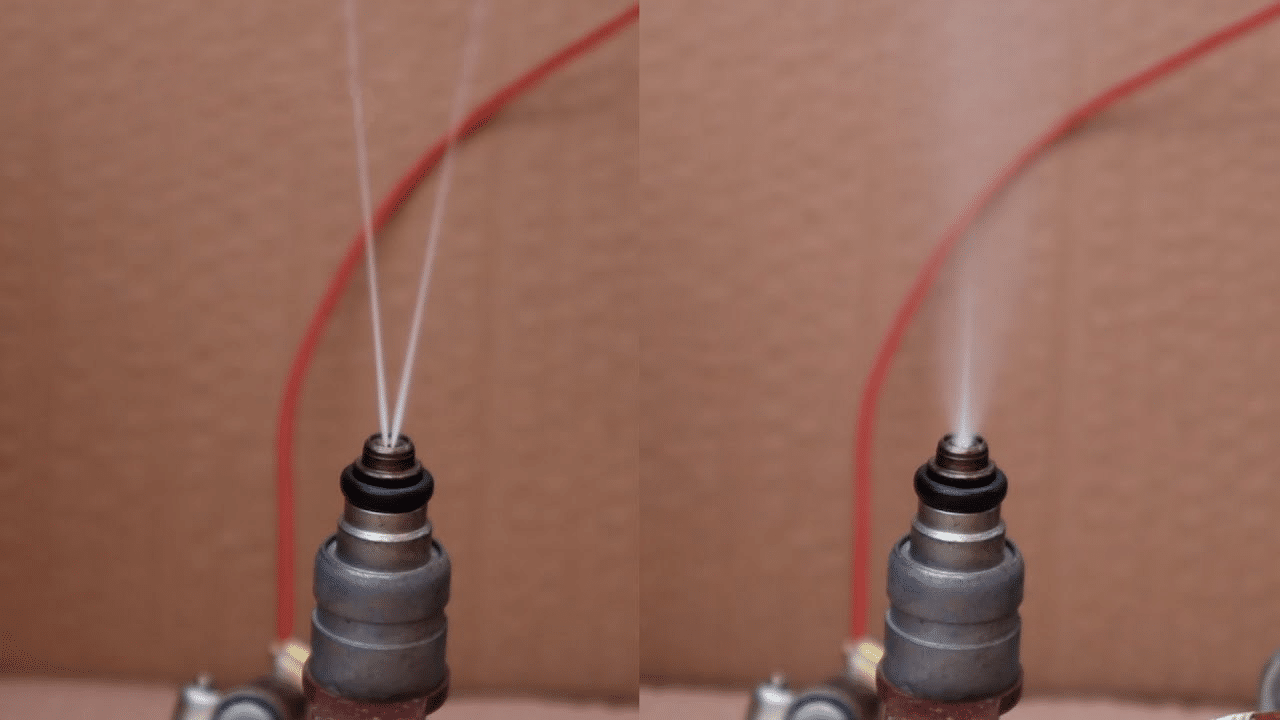

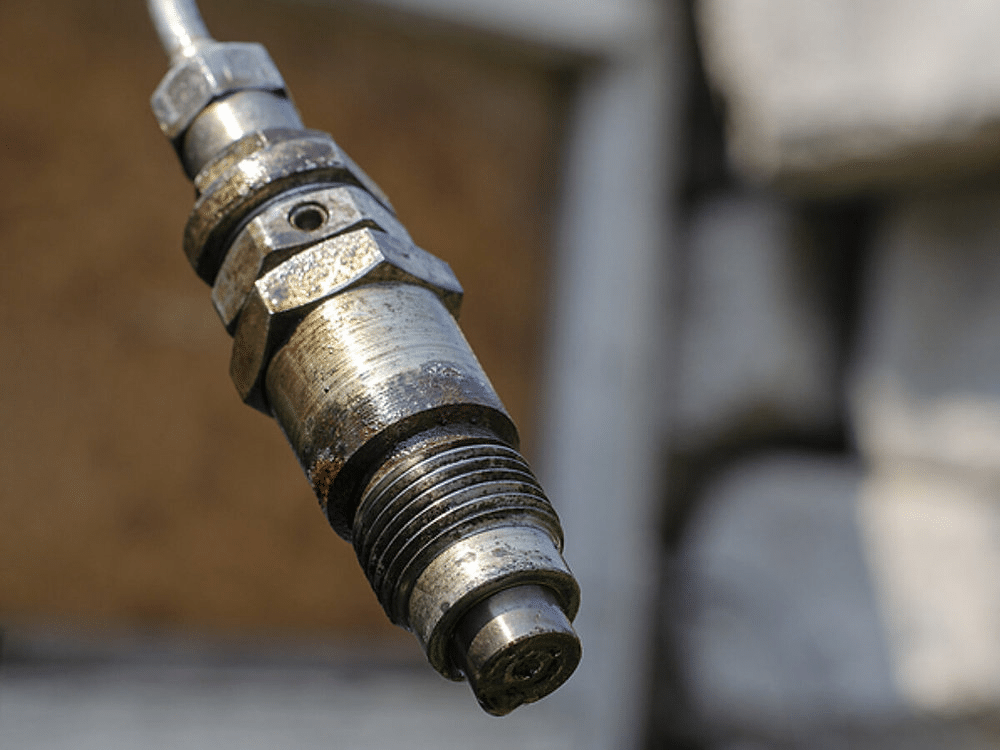

Clogged Injectors

Clogged injectors occur when dirt, debris, or other contaminants obstruct the injectors, leading to engine misfires, rough idling, and reduced fuel economy. To address this issue, fuel additives from LIQUI MOLY, Motul, GAT, and other providers can be used to clean the injectors.

Additionally, professional fuel injection cleaning services such as LIQUI MOLY Jetclean can be employed for thorough cleaning. In some cases, it might be necessary to replace the clogged injectors, with costs varying depending on the type of injector and the make and model of the vehicle.

Leaking Injectors

Leaking injectors refer to injectors with compromised seals, resulting in fuel leakage. This can cause engine misfires, rough idling, and reduced fuel efficiency.

To fix leaking injectors, replacing the seals, cleaning the fuel filters, and adjusting the fuel pressure are potential solutions. Fuel injector cleaners may also be used to help clean and lubricate the injectors.

Faulty Sensors

Faulty sensors, such as a mass air flow sensor, can have a significant impact on fuel injection performance, leading to misfires, decreased fuel economy, and elevated emissions. These sensors may malfunction due to age, wear and tear, or contamination.

To address faulty sensors, replacing, cleaning, or recalibrating the sensor are viable options. Regular sensor maintenance ensures optimal fuel injection performance and overall engine efficiency.

Advances in Fuel Injection Technology

As technology continues to evolve, so do fuel injection systems. Recent advancements in fuel injection technology include common-rail injection systems and air-assisted fuel injection. These innovations offer improved performance, efficiency, and emissions reduction, making them a welcome addition to the world of automotive engineering.

Common-Rail Injection Systems

Common-rail injection systems provide increased low-end torque and decreased combustion noise. This system utilizes a high-pressure fuel rail to deliver fuel to the injectors, allowing for more precise fuel delivery and improved engine performance.

Common-rail injection systems have become increasingly popular in both gasoline and diesel engines, offering a range of benefits over traditional fuel injection systems.

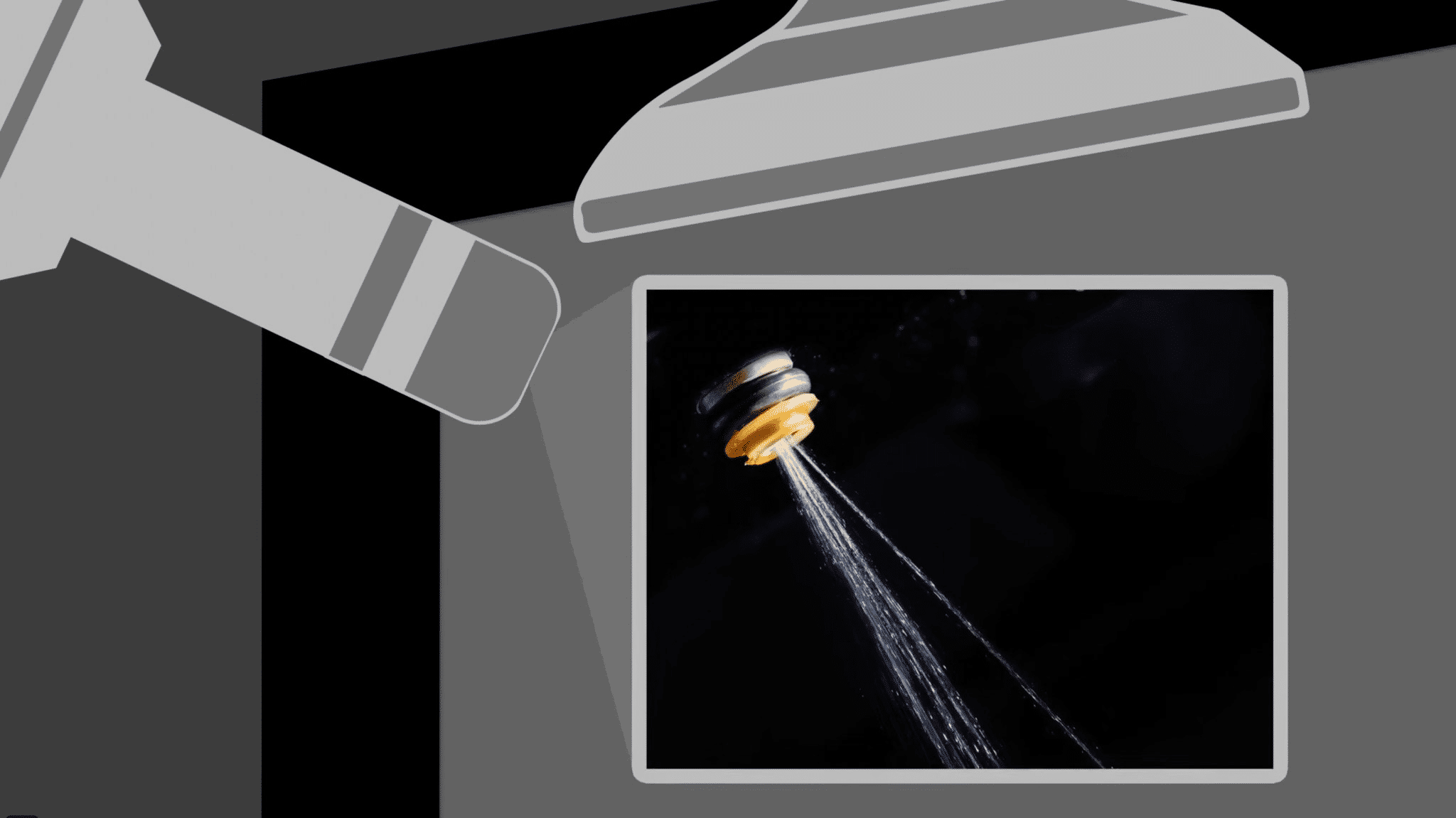

Air-Assisted Fuel Injection

Air-assisted fuel injection is a system that combines fuel and compressed air to create atomized fuel droplets for enhanced combustion efficiency. This system typically utilizes two injectors: a fuel injector and an air injector. By improving the atomization of the fuel, air-assisted fuel injection provides improved fuel economy, decreased emissions, and heightened engine performance.

This innovative technology shows promise for small two-stroke engines, where improved fuel atomization can lead to significant performance improvements.

Methods to clean fuel injectors

Keeping fuel injectors clean and free of deposits is a prerequisite for maintaining optimal engine performance and efficiency. Various methods are available for cleaning fuel injectors, including fuel additives, professional cleaning services, and replacement.

Awareness of the various options and their effectiveness can guide your decisions in fuel injector maintenance.

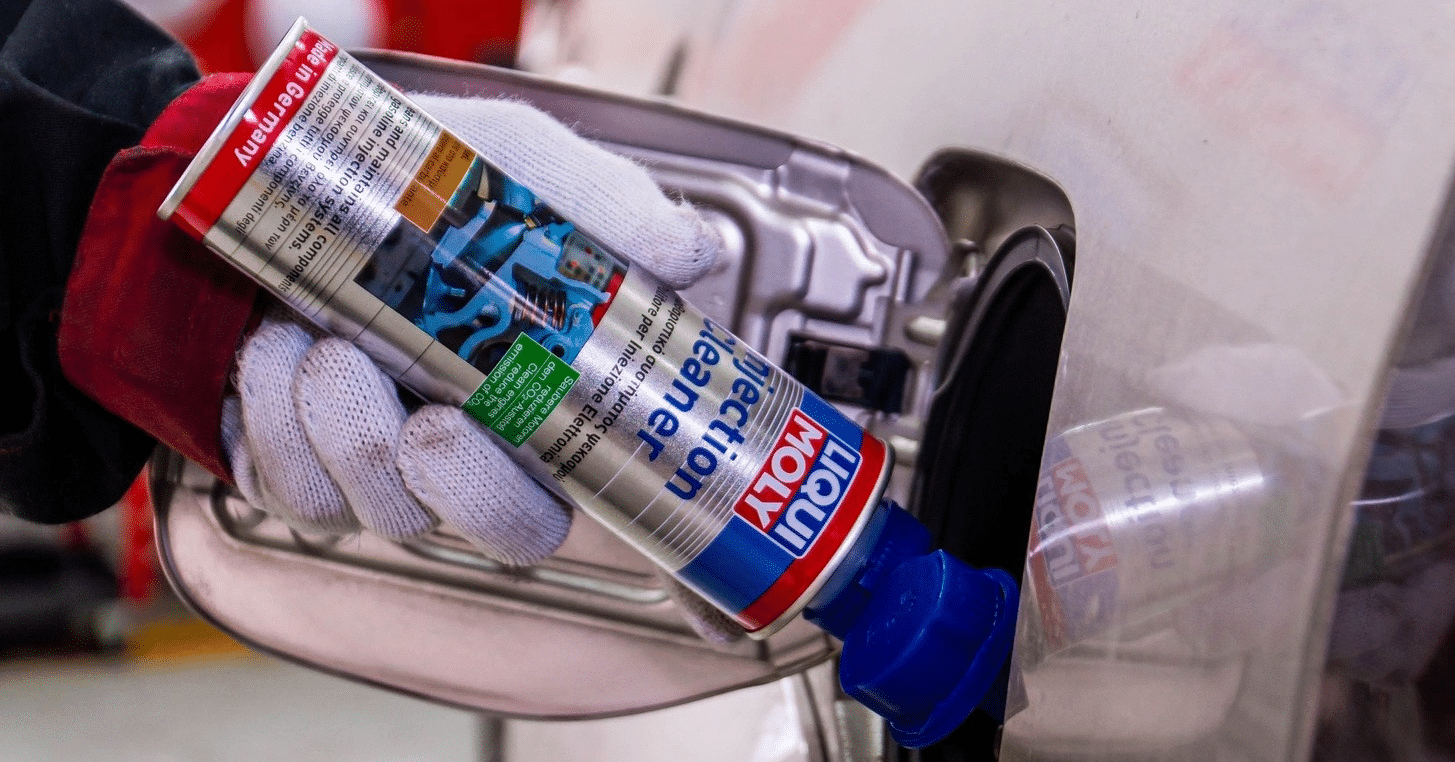

Fuel additives to clean fuel injectors from LIQUI MOLY, Motul, GAT and others

Fuel additives that can be used to clean fuel injectors include:

Red Line SI-1 Complete Fuel System Cleaner

Chevron Techron Concentrate Plus

Liqui Moly Jectron

K&N Performance+ Fuel System Cleaner

Red Line Complete Fuel System Cleaner

By diminishing deposits and accumulation in fuel injectors, these additives have the potential to enhance engine performance and fuel economy.

It is suggested to utilize fuel additives every 3,000 to 5,000 miles to guarantee optimal performance.

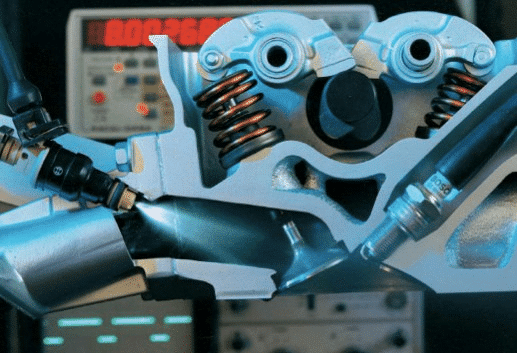

Fuel injection cleaning methods like LIQUI MOLY Jetclean

Another option for cleaning fuel injectors is professional fuel injection cleaning services, such as LIQUI MOLY Jetclean. These services offer thorough cleaning and can address more severe injector issues that fuel additives may not be able to resolve.

Engaging professional fuel injection cleaning services can result in improved engine performance, reduced emissions, and increased fuel efficiency.

Replacing fuel injectors and associated costs

In some cases, it might be necessary to replace fuel injectors. The process for replacing fuel injectors involves carefully prying each injector out by hand and inserting the new injector into the same hole.

The cost of replacing fuel injectors can vary depending on the type of vehicle and the type of injector being replaced. Generally, the cost of replacing a single fuel injector can range from $100 to $400.

Summary

In conclusion, understanding the complexities of fuel injection systems is critical for maintaining optimal engine performance and efficiency. By exploring the various types of fuel injectors, their components, common issues, and recent advancements in fuel injection technology, you can make informed decisions when it comes to vehicle maintenance and performance. Stay informed and keep your engine running smoothly for years to come.

Frequently Asked Questions

How often does a car need a fuel injection?

A fuel injection service is recommended every 45,000 miles or three years to maintain optimal performance.

Is fuel injection good or bad?

Fuel injection systems provide better fuel economy and require less maintenance compared to traditional carburettors. They are also more efficient and have fewer emissions. However, they come at a higher cost due to costlier parts and higher fuel consumption. Overall, fuel injection is a good choice.

What are the symptoms of a failing fuel injector?

Common symptoms of a failing fuel injector include engine stalls, misfiring, poor fuel economy, the RPM needle dancing, a check engine light, failed emissions, increased fuel consumption, rough performance, and surging/bucking under various throttle loads.

How much does a fuel injector cost?

Replacing a fuel injector can be costly, ranging from $300 to $900 depending on the vehicle, brand and location. Parts and labour for replacement can cost between $150 and $400.

What is the fuel injector system?

The fuel injection system is a modern method of atomising fuel at high pressure and mixing it with clean air, before entering the combustion chamber. It relies on an electronic control unit for its operation.